Innovative electronics production

The supermodern full-cycle production line is designed by the principle of maximum automation and is intended to the manufacturing of high quality electronic devices of any complexity

Maximally automated production

Maximally automated production

Process automated quality control

Process automated quality control

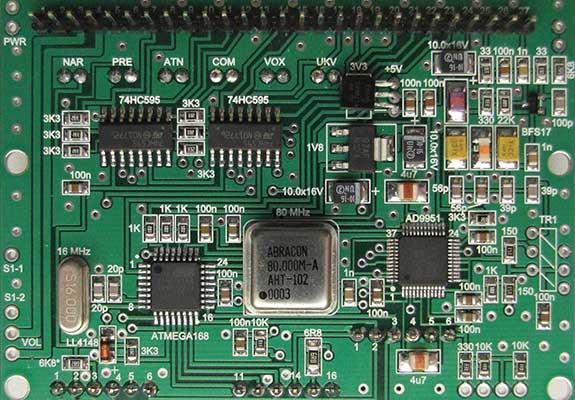

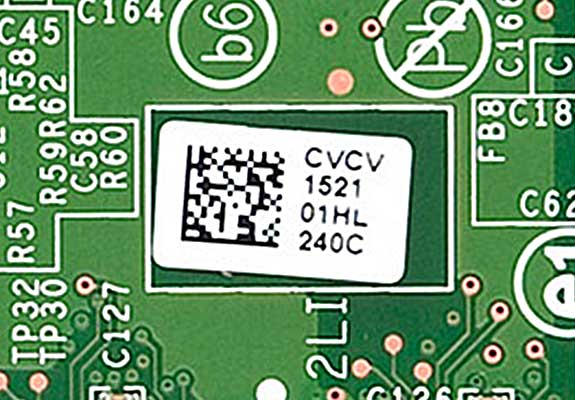

Nutek laser marking system. PCB marking

Nutek laser marking system. PCB marking

StarLine PRODUCTION

PCB laser marking with the unique code

100% durability

Clear identification of each PCB

Full traceability of a product lifecycle

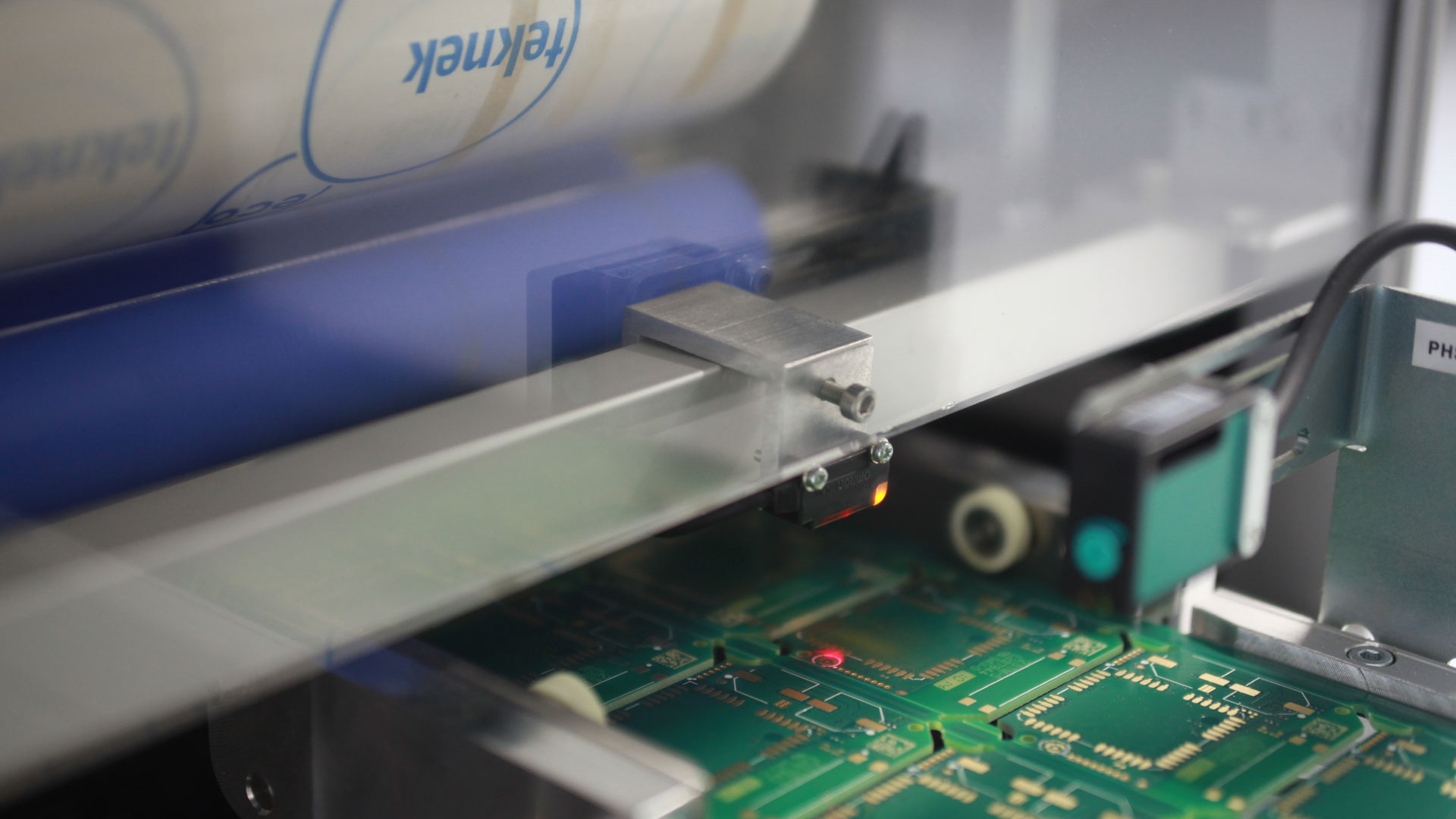

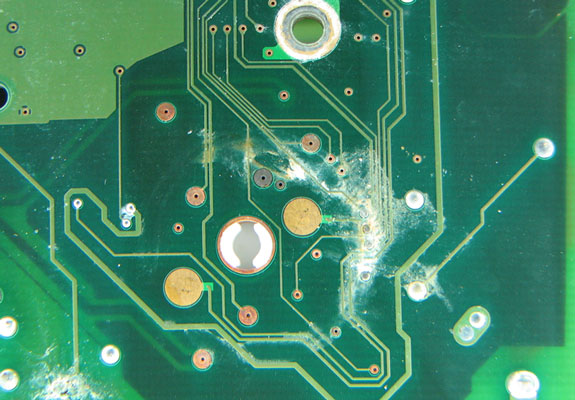

Teknek PCB cleaning system. Adhesive rollers remove micropollution from the PCB

Teknek PCB cleaning system. Adhesive rollers remove micropollution from the PCB

StarLine PRODUCTION

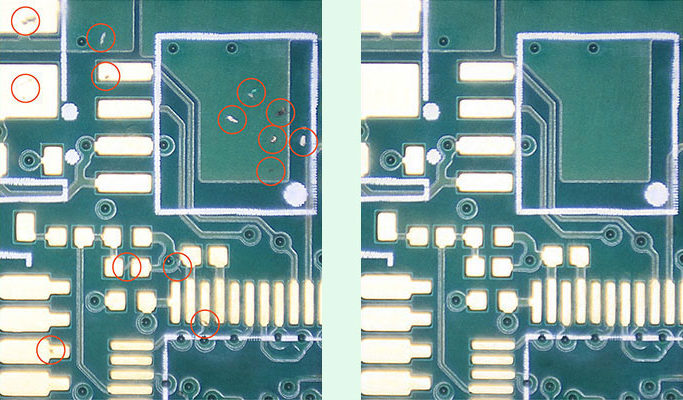

PCB before and after cleaning

Teknek adhesive rollers remove micropollution from the PCB

Cleaning provides high quality of the solder joints

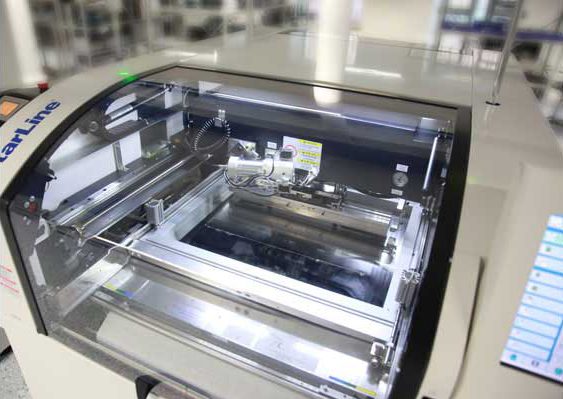

Panasonic SP-70 screen printer. Accuracy of solder paste application is 20 microns

Panasonic SP-70 screen printer. Accuracy of solder paste application is 20 microns

StarLine PRODUCTION

100% automation = 100% quality

АAutomatic solder supply. Continuous solder printing

Measurement of squeegee’s height on stencils. Stable quality

Application speed is 12 sec. with printing accuracy of 20 microns

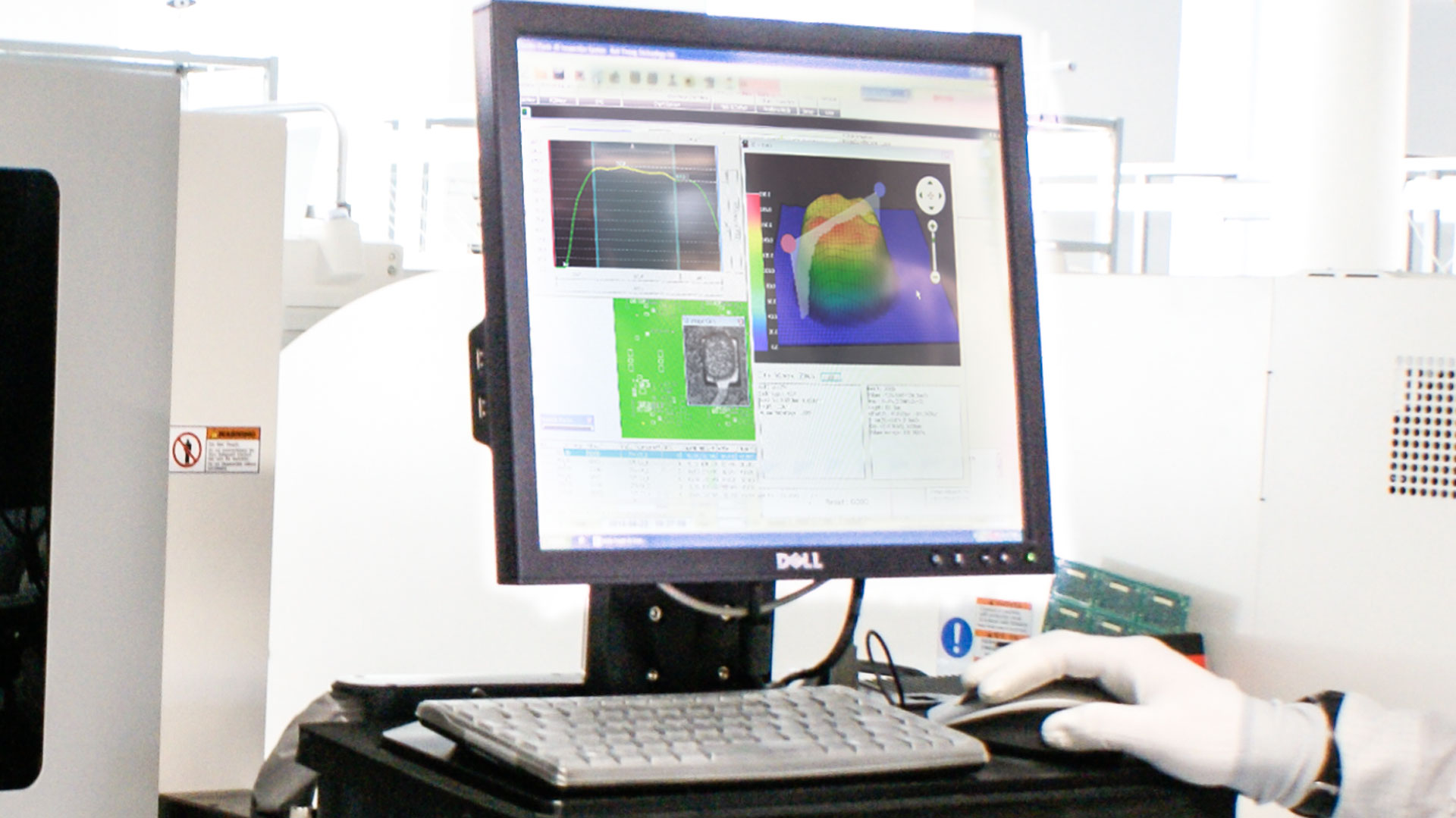

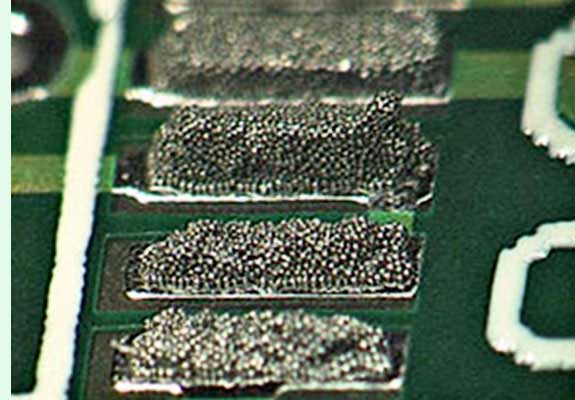

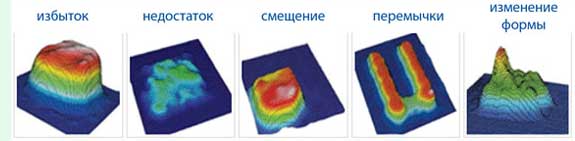

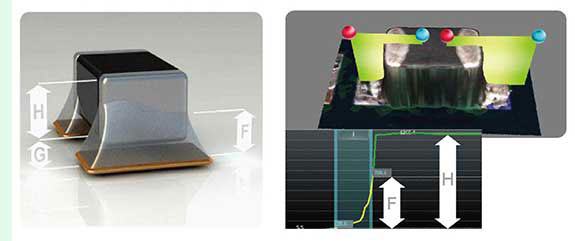

3D Koh Young solder paste inspection. 3D inspection of solder paste volume

3D Koh Young solder paste inspection. 3D inspection of solder paste volume

StarLine PRODUCTION

3D Koh Young solder paste inspection

3D measurement and defect detection of solder paste application:

100% 3D quality control of solder paste application in accordance with IPC 610 requirements

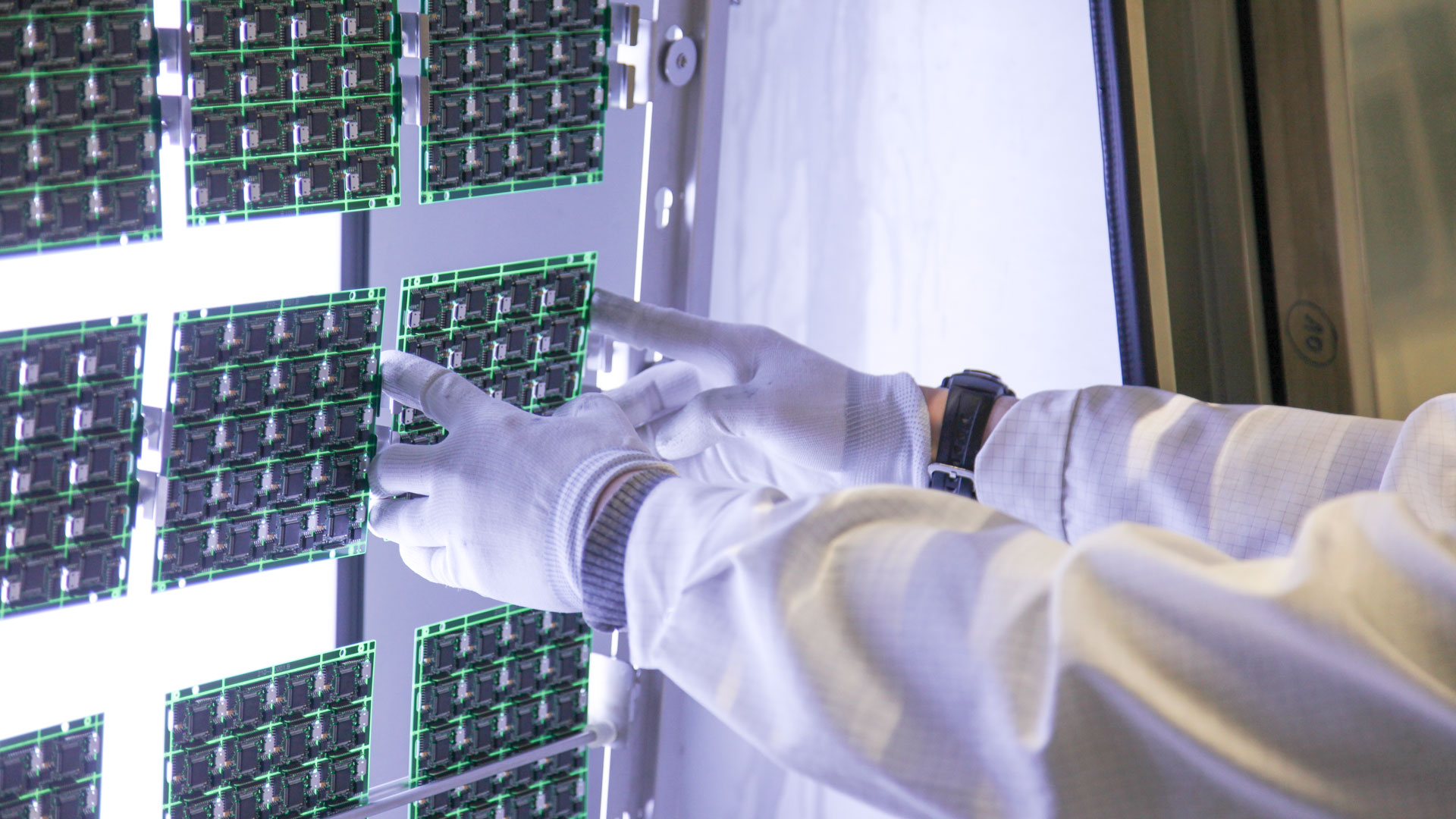

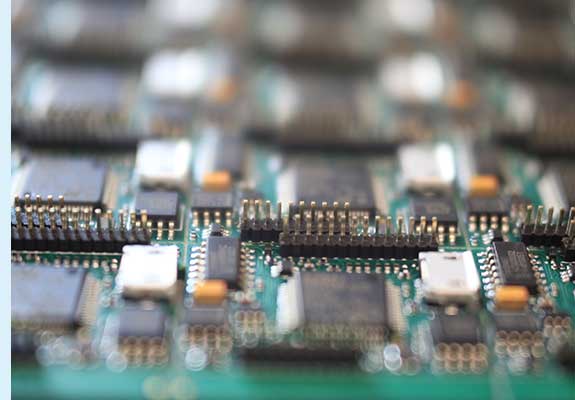

High-performance Panasonic NPM-W pick and place modular system. Velocity of up to 210 000 cph

High-performance Panasonic NPM-W pick and place modular system. Velocity of up to 210 000 cph

StarLine PRODUCTION

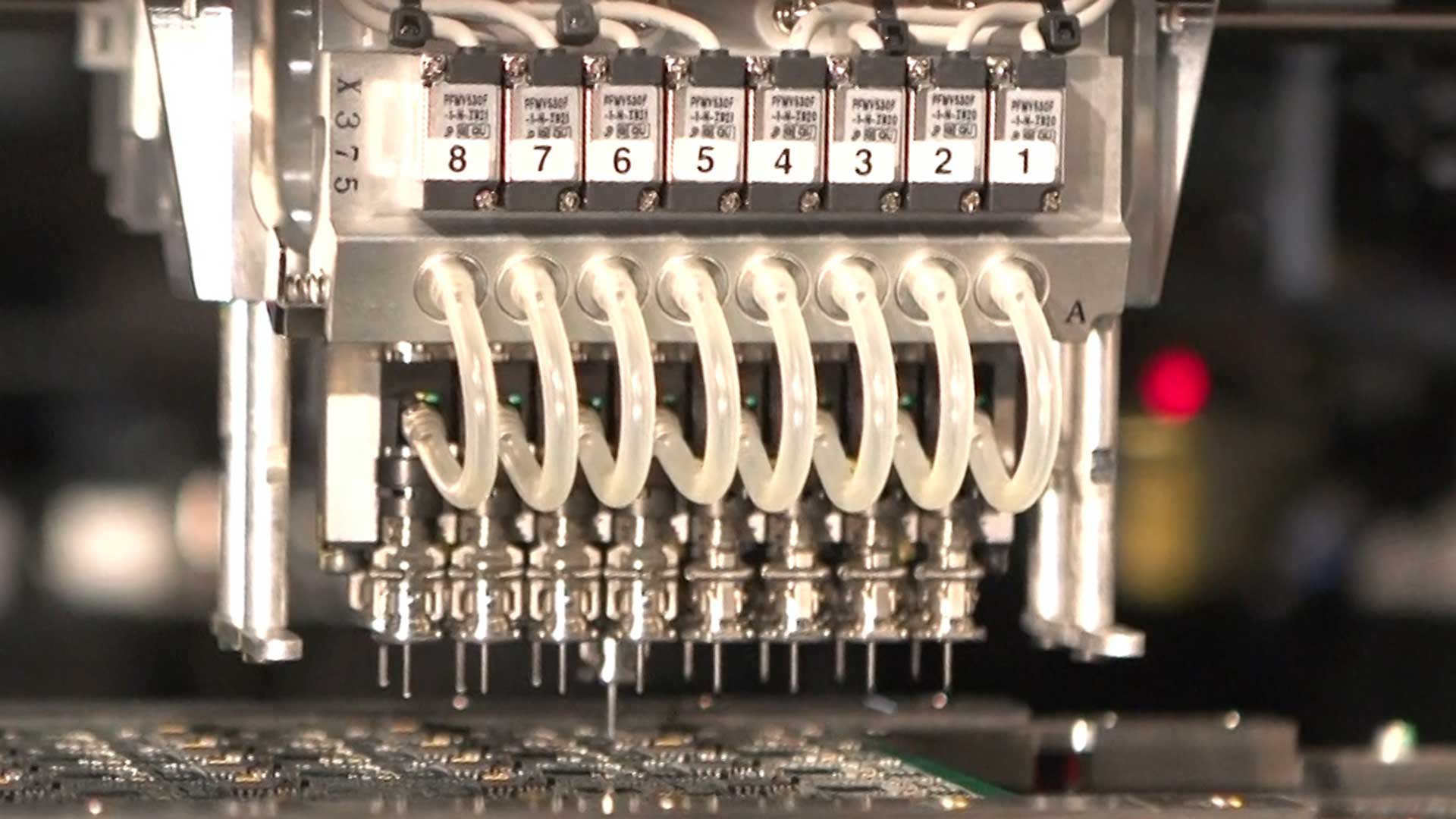

High-performance Panasonic NPM-W pick and place modular system

Placement of components with 01005 size

Velocity of up to 210 000 cph with placement accuracy of 20 microns

Placement of connectors on the Pin&Paste technology

Placement of components with non-standard shape

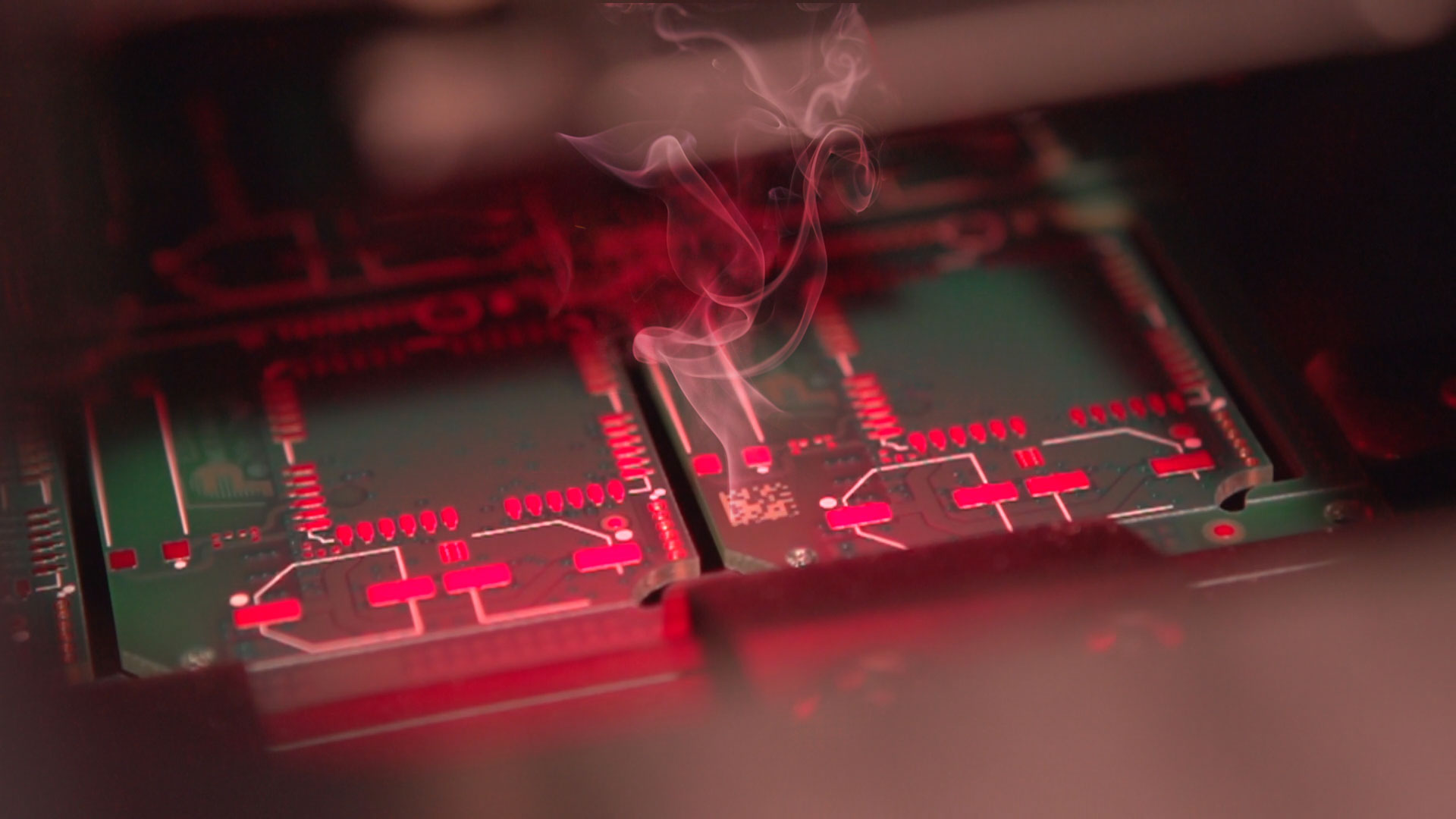

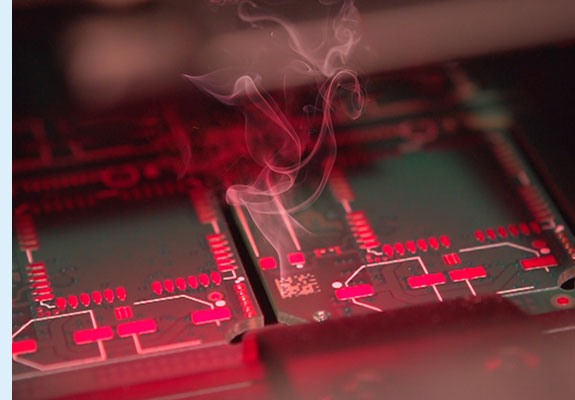

Senju SNR-1065 convection oven. 10 heater zones, 2 cooling zones

Senju SNR-1065 convection oven. 10 heater zones, 2 cooling zones

StarLine PRODUCTION

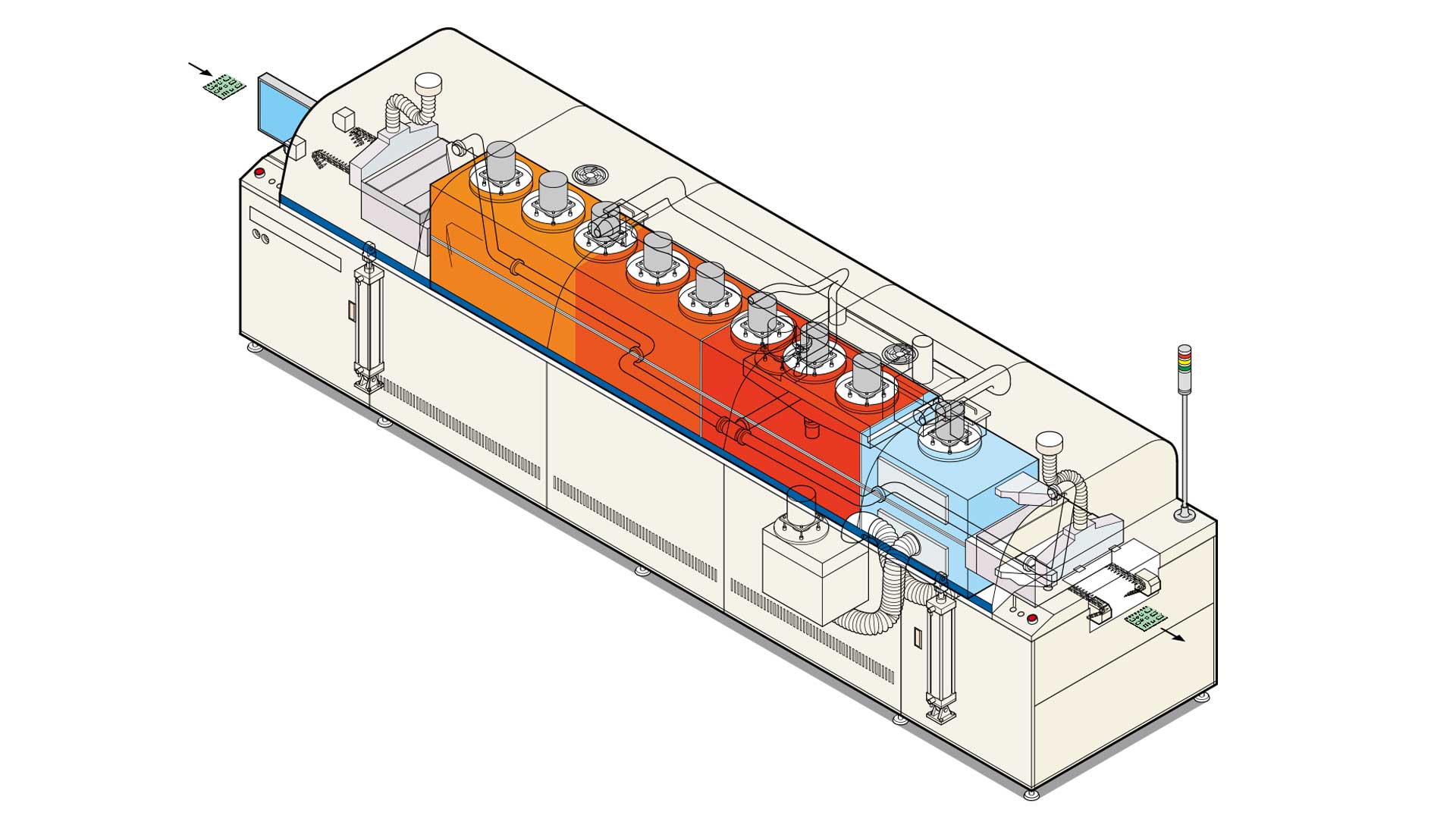

Senju SNR-1065 convection oven

High quality solder joints due to active cooling

Use of PB-free technology

Stable temperatures in the zones of ±1°C

Energy efficiency and environmental friendliness

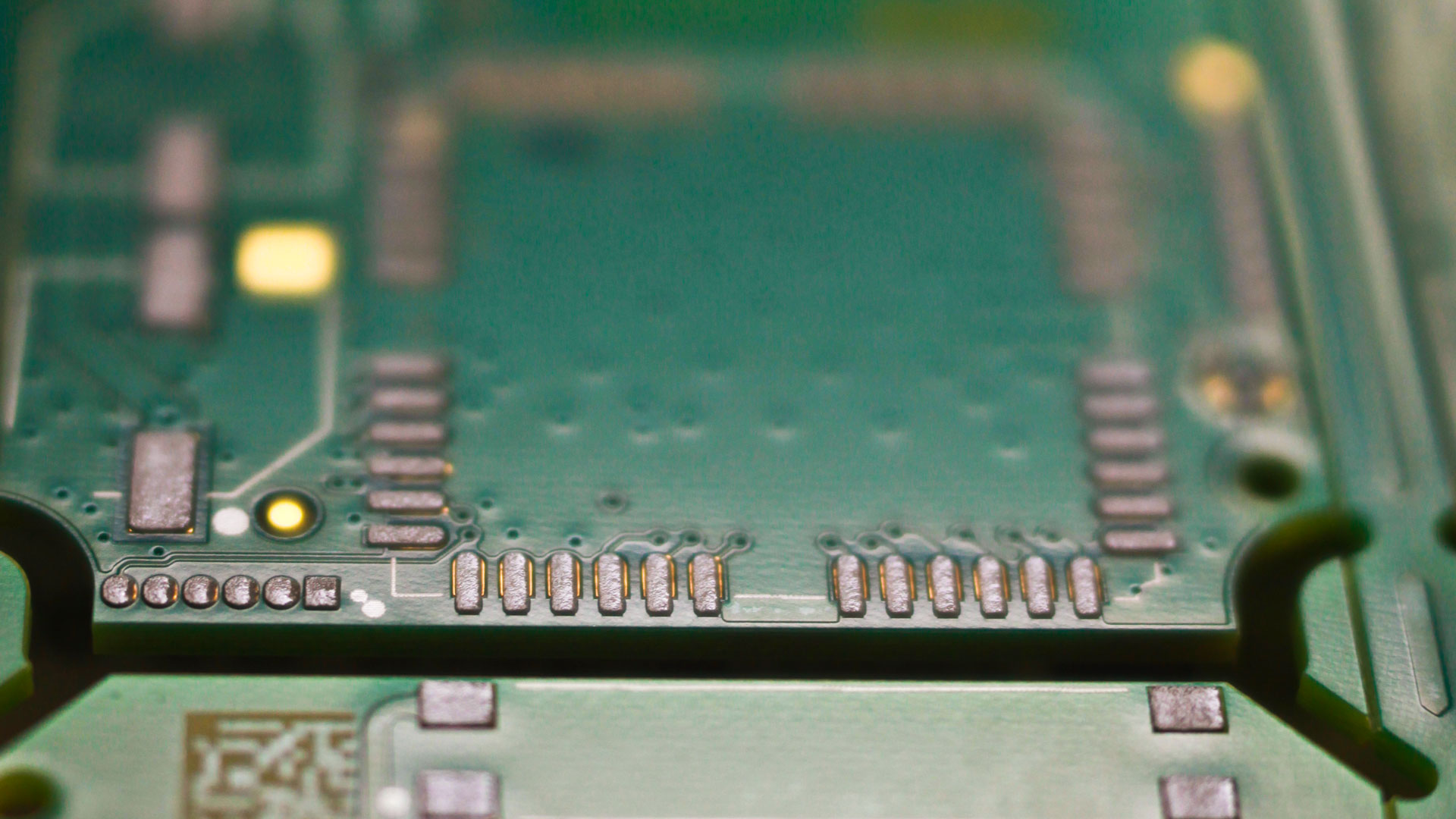

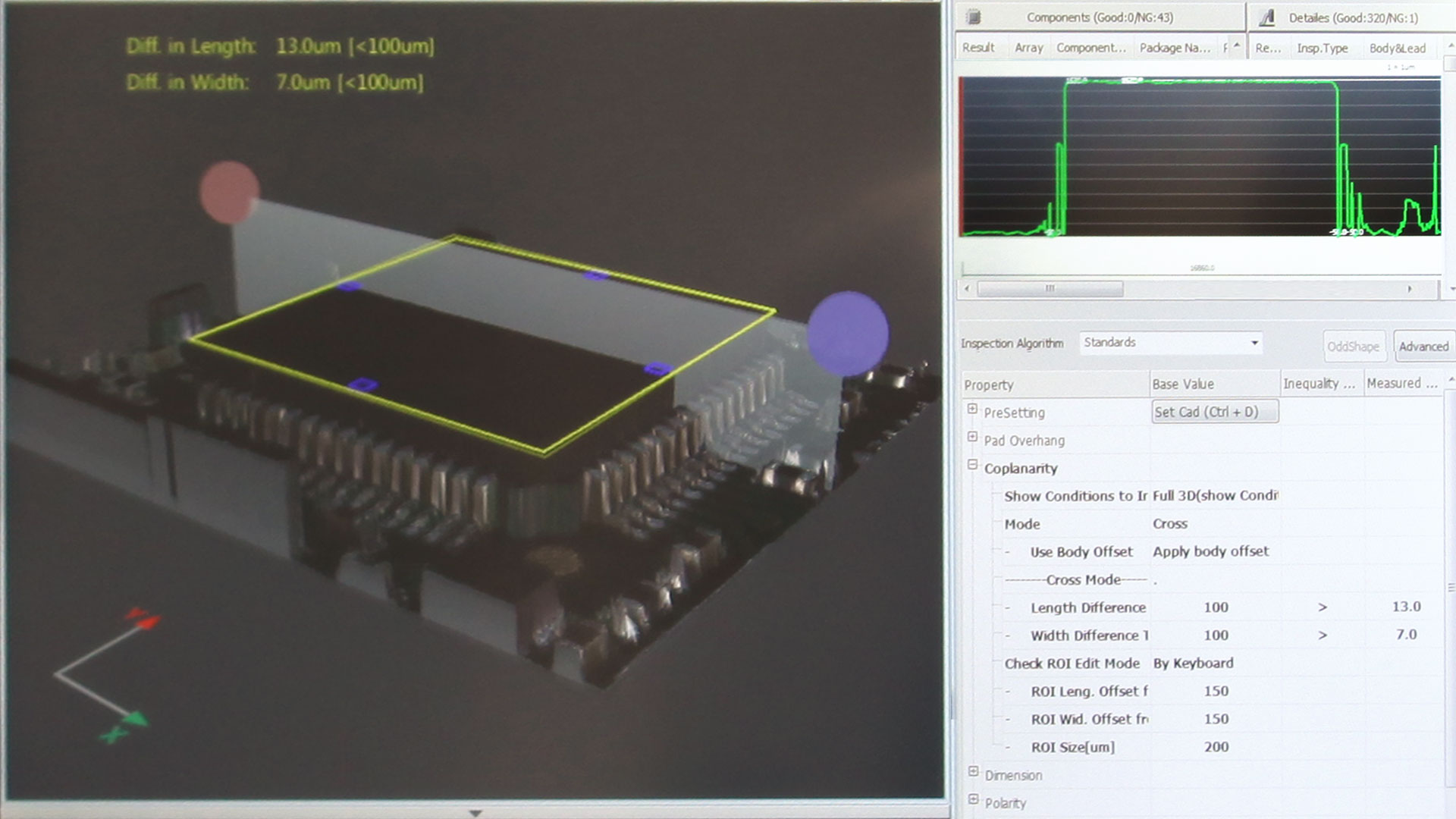

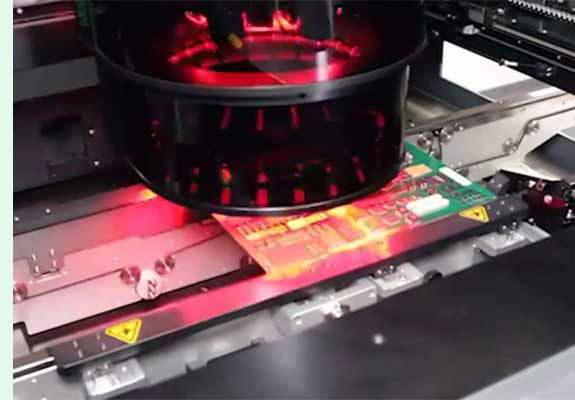

Koh Young Zenith 3D Automated Optical Inspection 100% quality control

Koh Young Zenith 3D Automated Optical Inspection 100% quality control

StarLine PRODUCTION

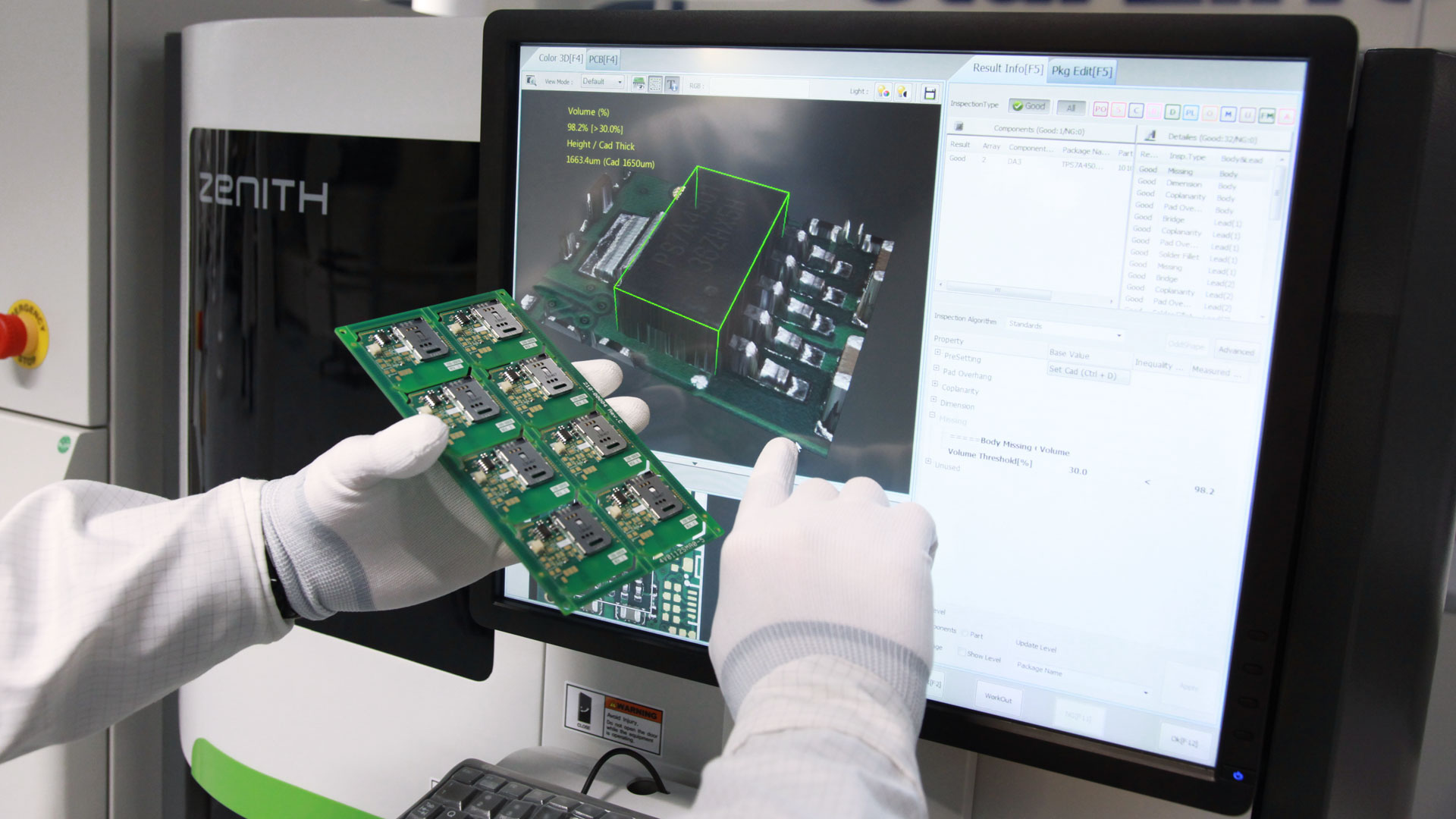

Koh Young Zenith 3D AOI inspection

High-speed 3D camera

Component height and volume measurement

Component inspection in accordance with IPC-A-610 standards

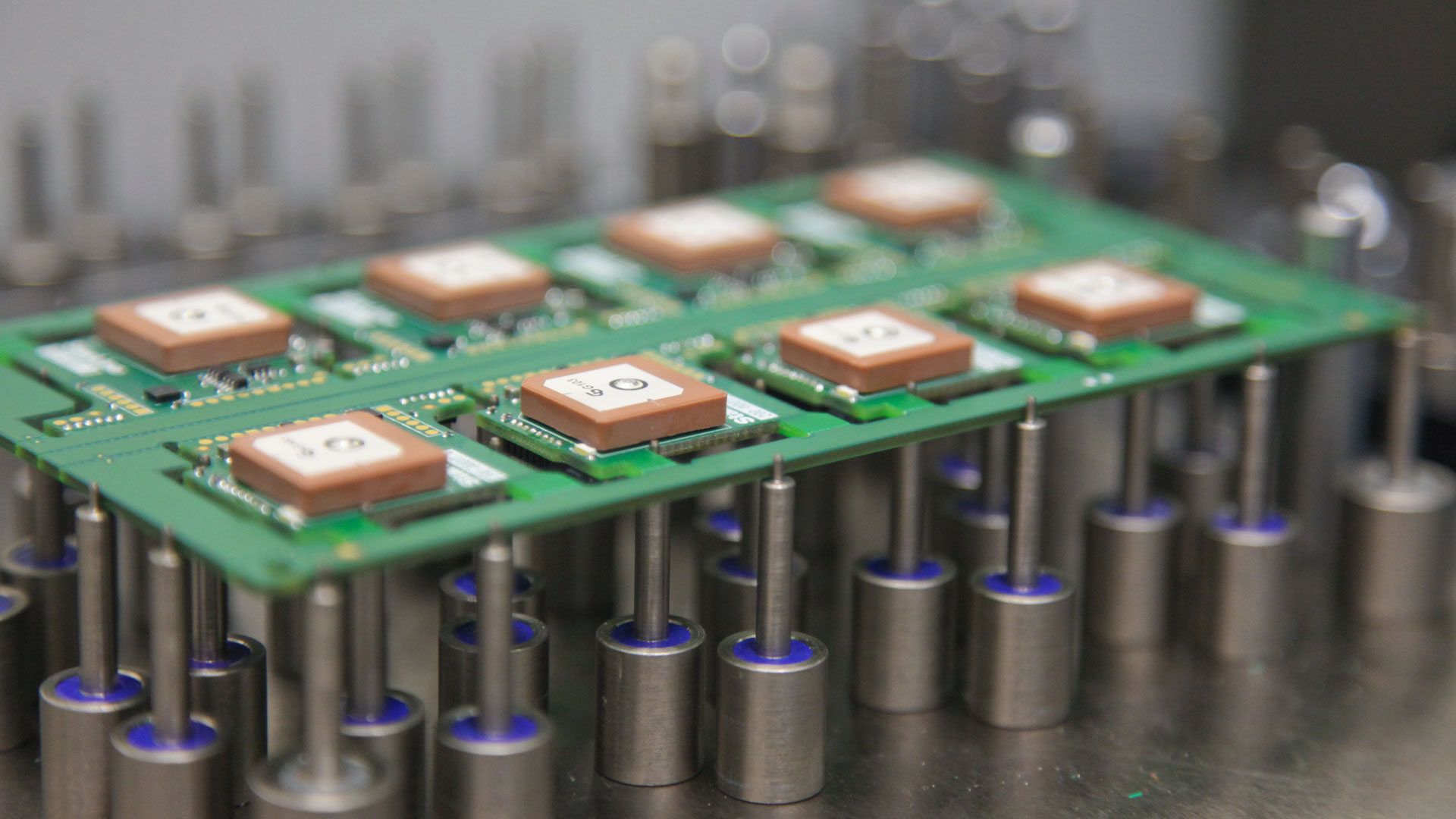

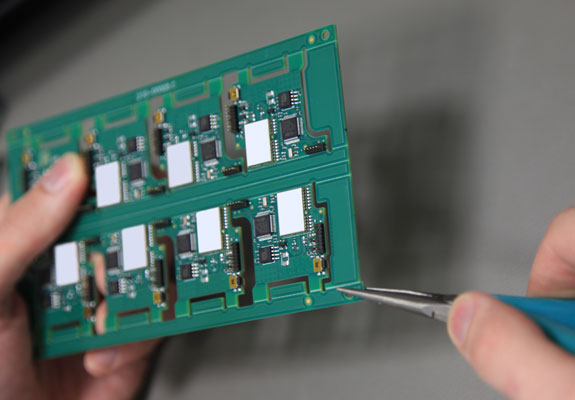

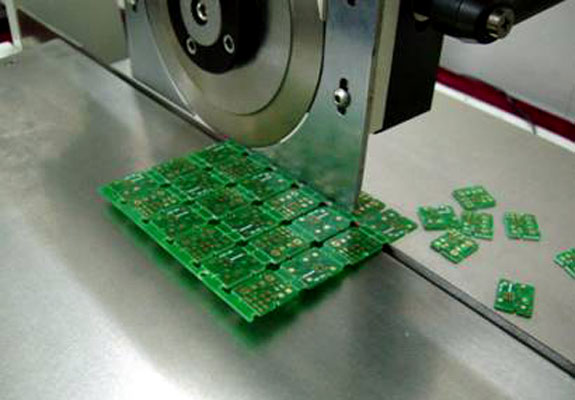

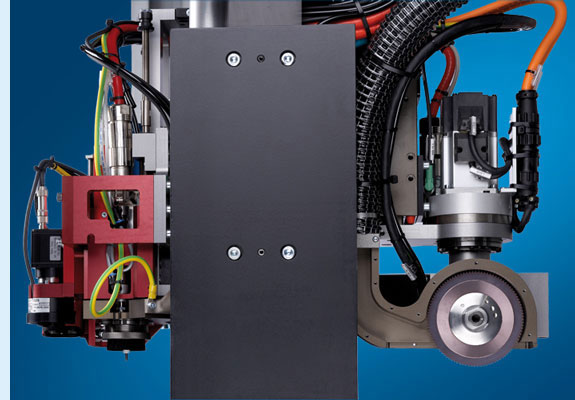

Automatic PCB separator SAR-1300 Disk and milling PCB separating

Automatic PCB separator SAR-1300 Disk and milling PCB separating

StarLine PRODUCTION

Automatic PCB separating SAR-1300

High accuracy and repeatability of the separation

Separation by means of disk and milling cutter

ESD protection

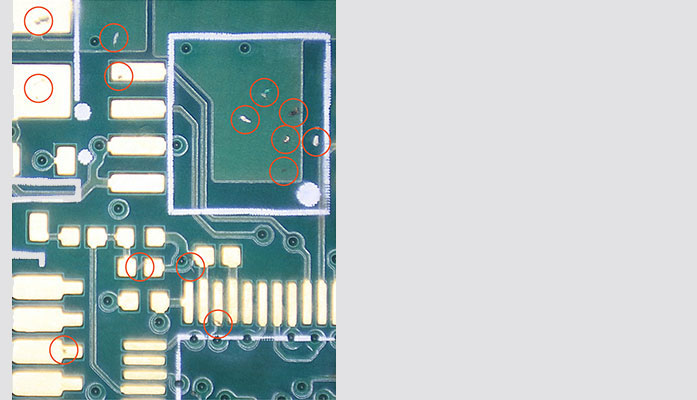

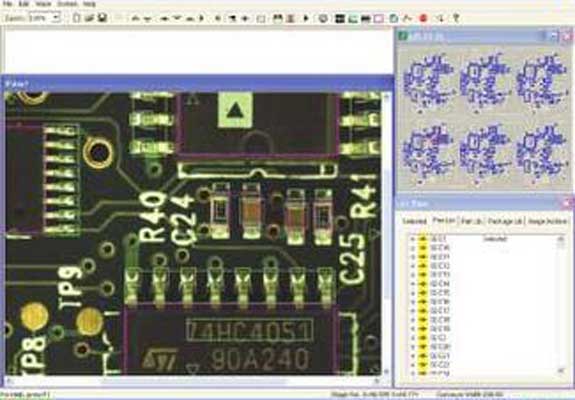

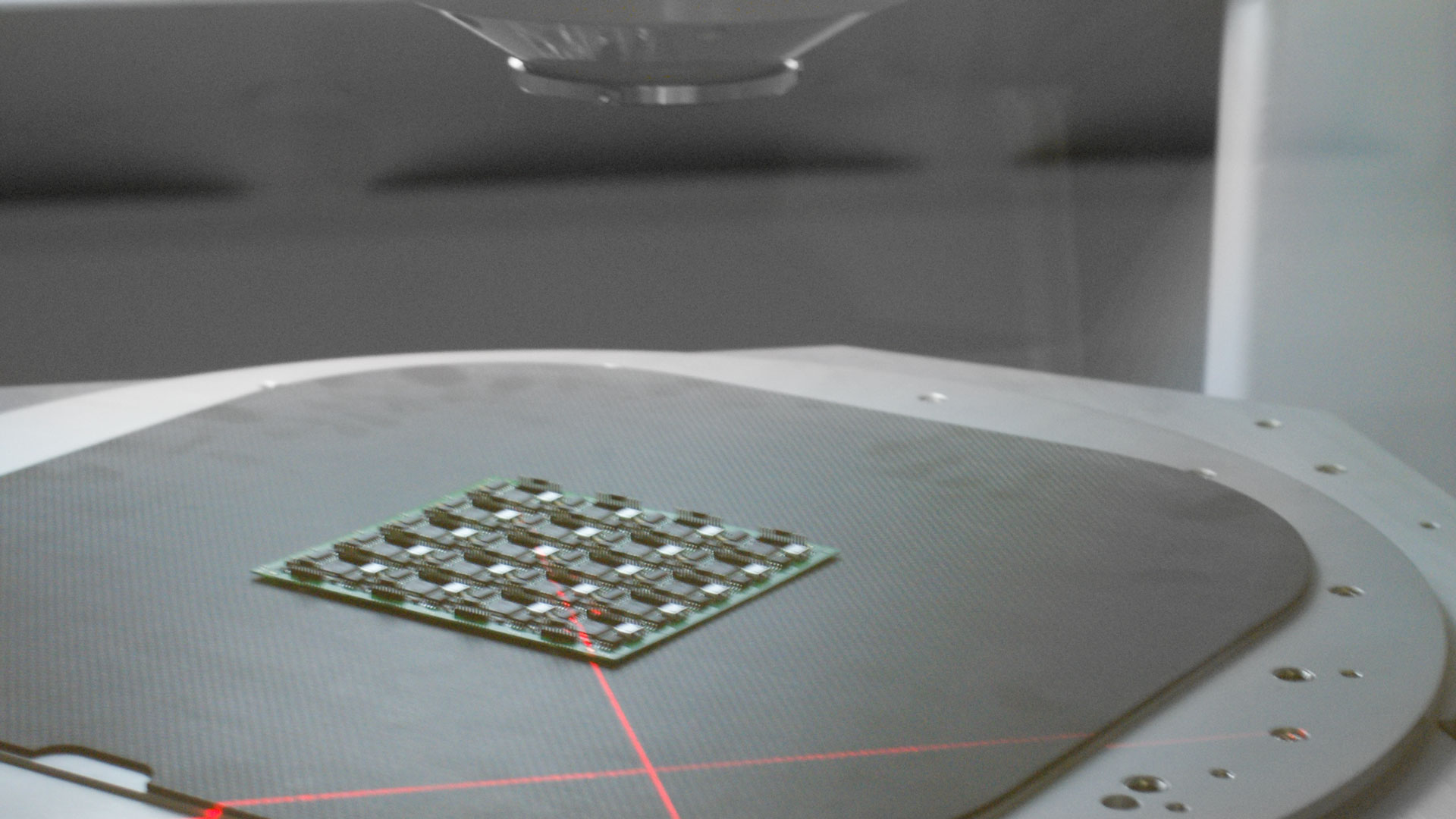

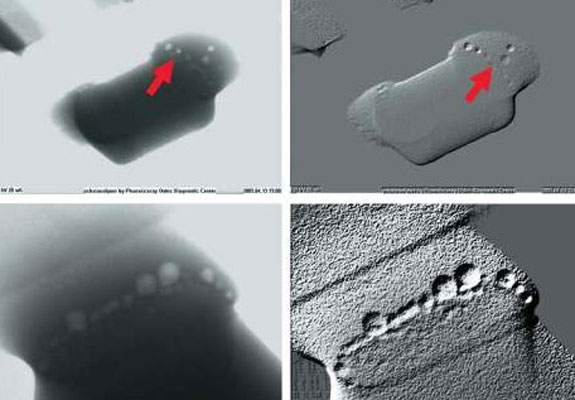

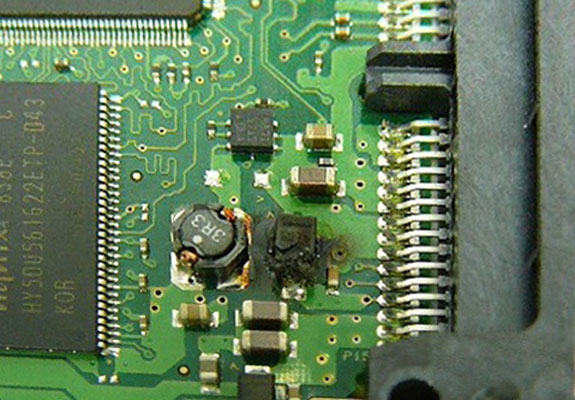

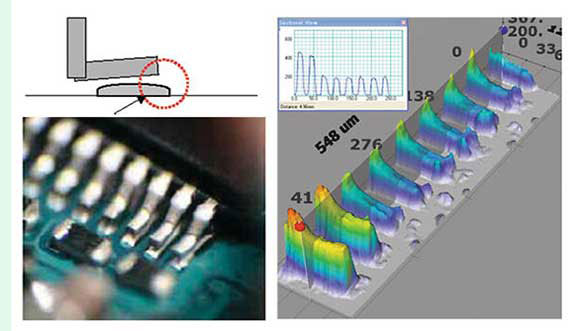

X-ray control. Quality control of the solder joints

X-ray control. Quality control of the solder joints

StarLine PRODUCTION

X-ray control

Quality control of mounted complex components such as BGA, QFP, FlipChip, etc.

Quality control of the solder joints: short circuit, hollow spaces in solder joints

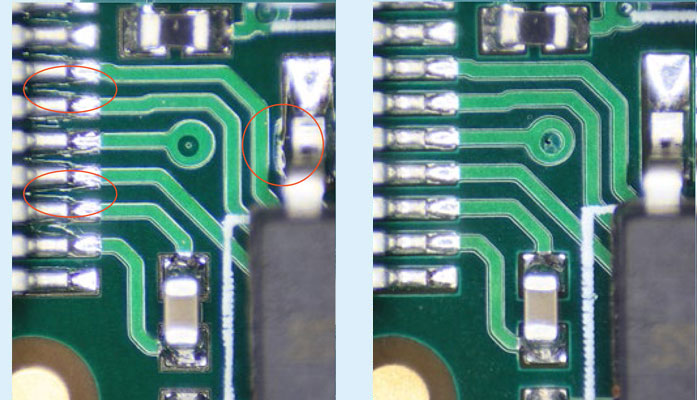

Super Swash PCB washing

Super Swash PCB washing

StarLine PRODUCTION

PCB before and after washing

Automatic PCB washing

Drying by heated air with the use of air knives

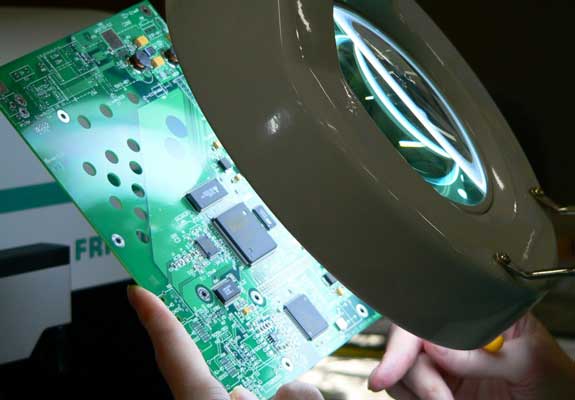

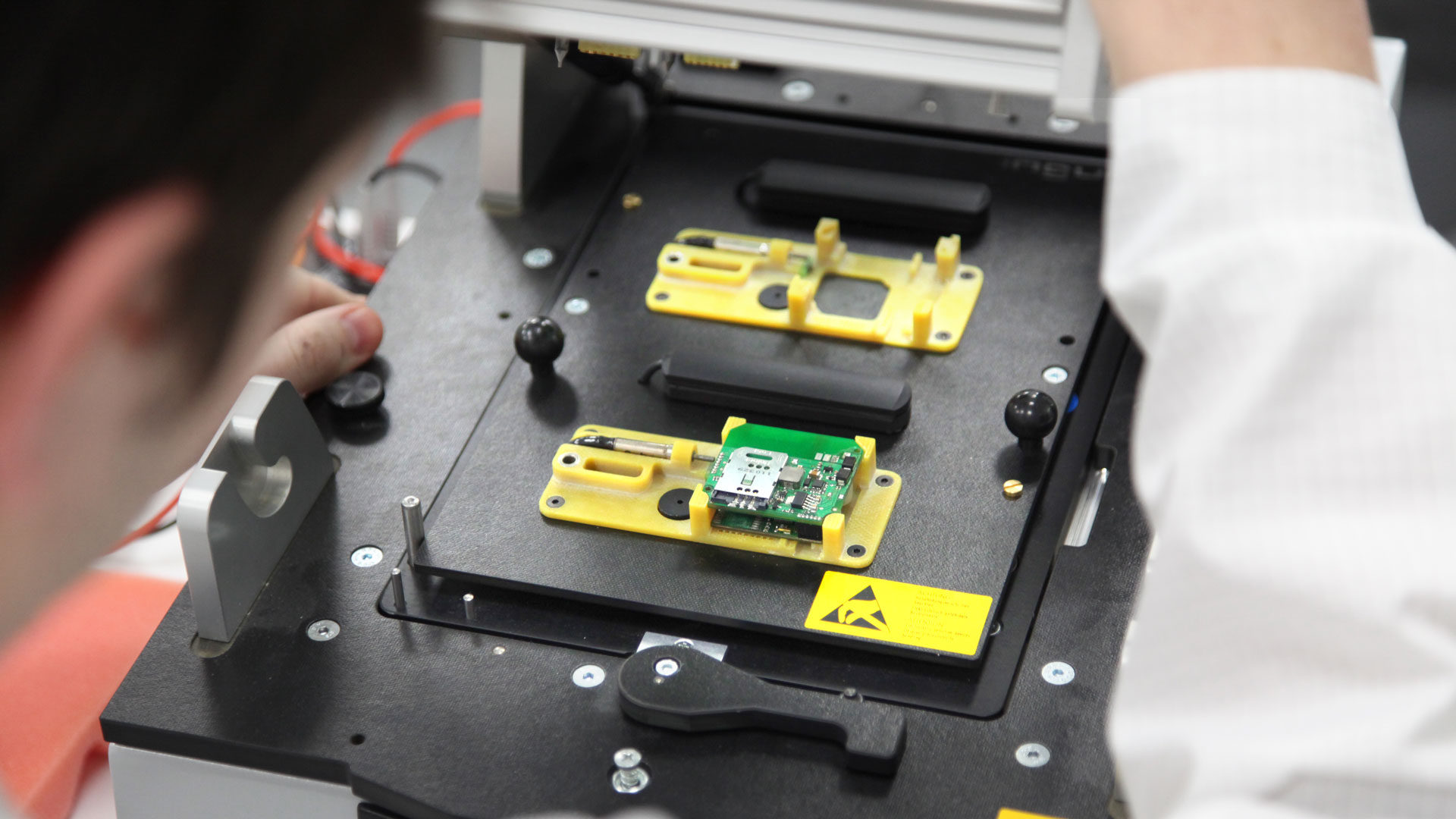

Functional testing

Functional testing

StarLine PRODUCTION

Functional product testing

100% checking of products

Guarantee of reliable work

Русский

Русский